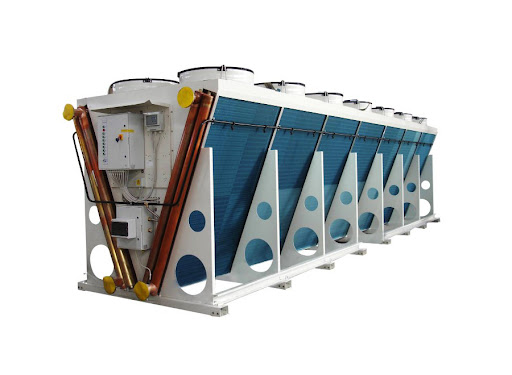

Klatra exchangers have a major influence on the overall system performance in every free cooling system, regardless of the selected process version. Kaltra dry coolers are the industry standard for basic cooling modes. Each is designed to provide optimal and complete counterflow, which in turn provides the highest heat transfer efficiency. Alfa Laval heat exchangers are designed to push the boundaries of heat transfer capabilities. The efficiency of dry cooling tower exchangers eliminates the possibility of stagnation zones and reduces fouling, ensuring maximum performance levels with minimum operating costs.

The pros of Kaltra dry coolers are:

- Reduction of water consumption by up to 95% compared to a standard cooling tower.

- No water treatment is required.

- Ideal water temperature thanks to a precise control system that continuously coordinates the operation of the fans and, if necessary, activates the adiabatic chamber.

- Maximum uptime thanks to zero rainfall, robust design and use of acrylic-coated heat exchangers.

- Up to 95% less energy consumption compared to an air-cooled central chiller.

- High performance and more compact dimensions compared to dry liquid coolers.

The main unit of the free cooling system must be placed only in a heated room with a temperature above 0 C in order to avoid defrosting the glycol/water plate heat exchanger. The construction of the main unit supports it to be installed both on the floor of the building and on the wall. It is recommended to leave sufficient space for service and access to the control panel at the front (from the side of the opening doors) and at the ends of the main unit.

The hydraulic circuit of the main unit includes all the components necessary for operation:

- stainless steel pump;

- a liquid pressure gauge;

- plate copper-brazed heat exchanger;

- membrane expansion tank;

- safety valve;

- air vent;

- shut-off valves;

- control board.